For a general introduction to cause mapping, see

root-cause-analysis.php.

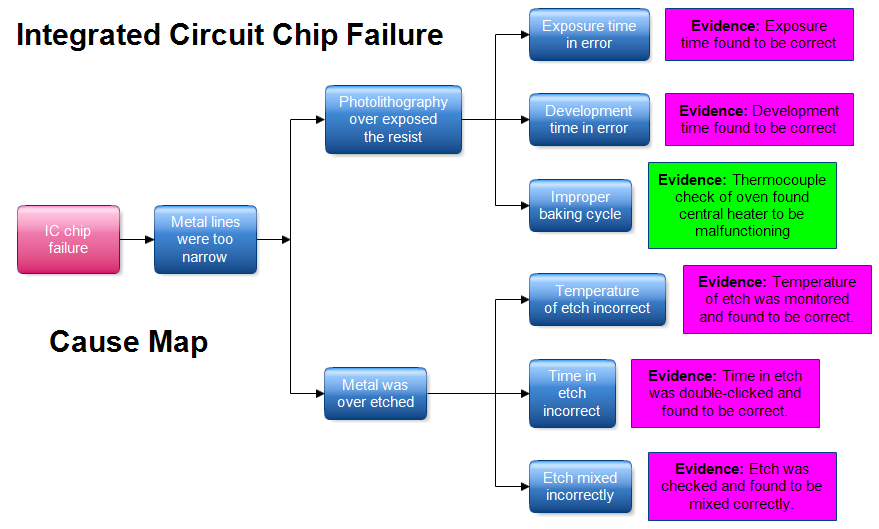

This cause map deals with a manufacturing problem. Too many integrated circuit

chips were failing. Inspections showed that the metal lines were too narrow. The

problem or primary effect is shown on the left in red. Color is not necessary in

cause mapping, but it is helpful to highlight the main problem. In this

cause map the evidence boxes are shown in purple to distinguish them from the

causes.

You read this chart from left to right and add the words "was caused

by" at each line. For example, "Metal was over etched" was caused

by "Temperature of etch incorrect" or "Time in etch

incorrect" or "Etch mixed incorrectly" or some combination of

these.

By checking all the possible causes, it was found that the oven which baked the

photoresist was malfunctioning and that caused the metal lines to be too narrow

and the IC chip to fail.

Professional Flowcharting Software

|

|

|

|

|

|

|

|